Plastics have revolutionized the manufacturing industry, and two of the most widely used plastic-forming techniques are blow molding and injection molding. Understanding the blow mold vs injection mold debate is crucial for manufacturers, designers, and engineers who want to choose the most suitable process for their specific applications. Although both methods are used to shape plastic materials, their techniques, end products, and purposes differ greatly.

This article explores the fundamental differences between these two manufacturing methods by analyzing their processes, applications, benefits, limitations, and cost implications. Whether you’re producing bottles or automotive parts, understanding these differences can help you select the optimal solution for your plastic production needs.

Understanding the Core Processes

The first step in the blow mold vs injection mold comparison is to understand how each molding technique works. Injection molding involves injecting molten plastic into a metal mold cavity under high pressure. Once the plastic cools and solidifies, the mold opens and ejects the finished product. This process is ideal for producing highly detailed and complex shapes with tight tolerances and is often used in mass production scenarios.

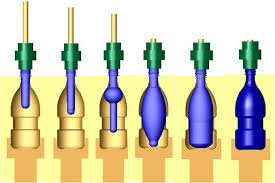

On the other hand, blow molding is a manufacturing process used to create hollow plastic parts, such as bottles and containers. In this process, plastic is melted and formed into a preform or parison. This parison is then clamped into a mold, and air is blown into it, forcing the plastic to expand and conform to the mold’s shape. Once cooled, the mold opens, and the final hollow part is ejected. This method is best suited for high-volume production of uniform, thin-walled products.

Key Differences in Equipment and Tooling

When analyzing blow mold vs injection mold, it’s vital to examine the equipment and tooling used in each method. Injection molding machines are more complex and typically consist of two main components: the injection unit and the clamping unit. The injection unit is responsible for melting and injecting the plastic, while the clamping unit holds the mold in place and applies the necessary pressure to form the part.

In contrast, blow molding machines vary depending on the type (extrusion blow molding, injection blow molding, or stretch blow molding), but all involve a mechanism for forming the parison and a blowing system. The molds used in blow molding are usually simpler and less expensive than those in injection molding due to lower pressure requirements. This can make blow molding more accessible for certain industries and smaller-scale production.

Product Types and Industry Applications

The blow mold vs injection mold debate also comes down to the types of products each method can produce. Injection molding is ideal for manufacturing solid parts such as medical devices, automotive components, containers, and precision gears. It’s especially advantageous for products that require intricate detail, consistent quality, and repeatability in large volumes.

Meanwhile, blow molding is specifically used to produce hollow objects. This includes plastic bottles, fuel tanks, watering cans, and other lightweight, thin-walled containers. Industries such as food and beverage, pharmaceuticals, and household goods rely heavily on blow molding for packaging solutions. Because of its specialization in hollow parts, blow molding is often the go-to method for high-output bottle production.

Benefits and Limitations of Each Method

Understanding the pros and cons helps clarify the blow mold vs injection mold decision. Injection molding offers unparalleled precision, surface finish quality, and design complexity. It supports a wide range of materials and is highly efficient for large-scale production. However, the tooling and setup costs are high, and the initial investment can be substantial, making it less viable for low-volume production.

In contrast, blow molding excels in producing lightweight, cost-effective, and uniform hollow parts. The molds are generally less expensive, and cycle times can be short, especially for simple container designs. That said, blow molding lacks the precision and part complexity achievable with injection molding. It’s not suitable for parts that require intricate detailing or solid structures. Additionally, wall thickness control can be less consistent compared to injection molding.

Cost Considerations and Production Efficiency

Cost plays a critical role in choosing between the two processes. In the blow mold vs injection mold comparison, injection molding involves a higher upfront investment due to complex mold design and machine requirements. However, it becomes cost-effective over long production runs as the per-unit cost drops significantly. This makes it ideal for manufacturers looking to produce millions of parts with consistent quality.

On the other hand, blow molding has lower tooling and equipment costs, which can be beneficial for companies needing high volumes of hollow products quickly and affordably. The simplicity of blow molds contributes to lower maintenance and faster mold changeovers, increasing production flexibility. However, if a company needs products with detailed geometry or structural strength, the trade-offs in quality and precision may not justify the cost savings.

Conclusion

The choice between blow molding and injection molding ultimately depends on the specific needs of your project. If you require hollow parts like bottles or containers, blow molding is usually the most efficient and cost-effective solution. If your product demands complex geometry, tight tolerances, or solid components, injection molding is the better option despite its higher initial cost.

When evaluating blow mold vs injection mold, consider factors such as part design, material type, production volume, and budget. Both technologies have their strengths and limitations, and in many cases, manufacturers may use both methods for different product lines. Understanding the nuances of each process ensures smarter decisions, optimized production, and greater success in product development.