The global industrial sector is undergoing rapid transformation. Efficiency, sustainability, and innovation are now at the forefront of manufacturing processes. One key mineral supporting this shift is synthetic fluorspar, a refined alternative to naturally mined fluorspar. With growing demand across steel, aluminum, and chemical industries, the role of reliable Synthetic Fluorspar manufacturers has never been more critical.

In this blog, we explore the industrial significance of synthetic fluorspar, market trends, and why Tekor Minerals stands out as a global leader.

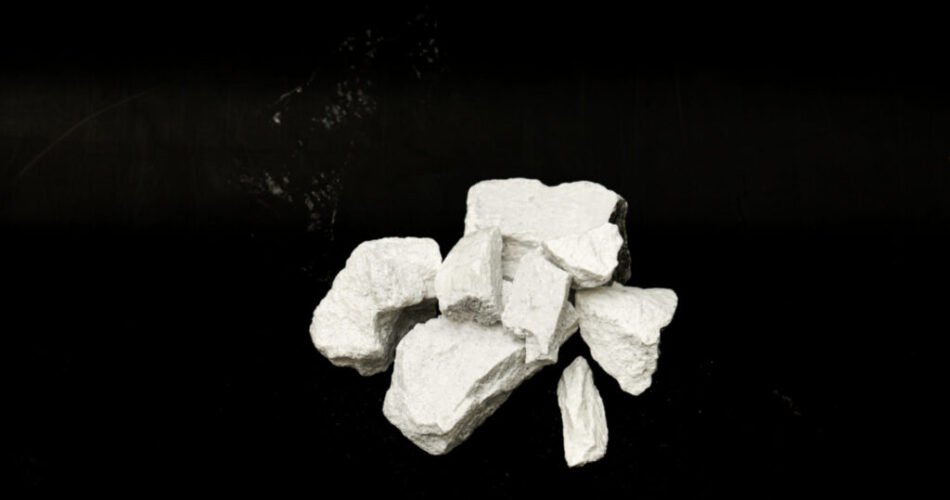

What is Synthetic Fluorspar?

Fluorspar (calcium fluoride, CaF₂) is essential for producing hydrofluoric acid, steel alloys, and aluminum. While natural fluorspar has long been used, it presents challenges such as variable purity, finite reserves, and environmental impact from mining.

Synthetic fluorspar offers a modern solution:

-

Higher Purity: Engineered to meet stringent industrial specifications.

-

Consistent Supply: Not affected by depletion of natural reserves.

-

Eco-Friendly: Minimizes environmental footprint by using industrial byproducts.

-

Cost-Effective in Production: Reduces waste and enhances process efficiency.

Industrial Applications

1. Steel Industry

Synthetic fluorspar acts as a flux, lowering melting points and removing impurities, which enhances steel quality and reduces energy costs.

2. Aluminum Production

Essential in electrolytic processes for refining aluminum, improving smelting efficiency, and cutting energy consumption.

3. Chemical Sector

Key for producing hydrofluoric acid, used in refrigerants, pharmaceuticals, and advanced materials like fluoropolymers.

4. Cement & Glass Manufacturing

Improves melting behavior and durability of end products while reducing energy requirements.

5. Ceramics & Enamels

Provides smoother finishes and greater thermal stability for high-quality ceramics.

Importance of Choosing the Right Synthetic Fluorspar Manufacturers

Partnering with the right supplier determines:

-

Quality Assurance: Reliable manufacturers deliver uniform mineral composition.

-

Cost Optimization: High-purity material reduces process inefficiencies and rejects.

-

Global Supply Security: Robust logistics prevent production delays.

-

Sustainability Alignment: Eco-friendly sourcing supports corporate ESG goals.

Tekor Minerals: A Global Leader in Synthetic Fluorspar Manufacturing

Tekor Minerals has built a strong reputation as one of the most trusted Synthetic Fluorspar manufacturers in the global market. Their focus on quality, customization, and innovation positions them as a preferred partner for industries seeking reliable raw materials.

What Sets Tekor Minerals Apart?

-

Advanced Manufacturing Technology: Ensuring superior product purity and consistency.

-

Customized Solutions: Tailored grades and packaging to meet diverse industry needs.

-

Global Reach: Efficient distribution ensuring timely deliveries worldwide.

-

Sustainability Leadership: Prioritizing eco-conscious production and waste reduction.

Global Market Trends for Synthetic Fluorspar

-

Shift Toward Synthetic Materials – Industries are moving away from natural fluorspar due to fluctuating supply and environmental concerns.

-

Growing Demand in Asia-Pacific – Rapid industrialization in China, India, and Southeast Asia is fueling synthetic fluorspar consumption.

-

Sustainability as a Key Driver – Stricter environmental regulations are pushing industries toward greener sourcing options.

-

Technological Advancements – Innovations in refining techniques are improving product quality and reducing production costs.

FAQs about Synthetic Fluorspar Manufacturers

Q1: What makes synthetic fluorspar better than natural fluorspar?

A1: Synthetic fluorspar offers higher purity, reliable supply, and reduced environmental impact compared to natural variants.

Q2: Which industries are the largest users of synthetic fluorspar?

A2: Steel, aluminum, chemical, cement, and ceramics industries rely heavily on synthetic fluorspar.

Q3: Why choose Tekor Minerals for synthetic fluorspar supply?

A3: Tekor Minerals combines advanced technology, global distribution, and eco-friendly production practices to deliver consistent quality.

Q4: Can Tekor Minerals provide custom grades of synthetic fluorspar?

A4: Yes, they tailor products to meet specific industrial needs and performance standards.

Q5: How can I connect with Tekor Minerals for inquiries?

A5: Visit Tekor Minerals to explore product specifications and request quotations.

Conclusion

The future of industrial manufacturing lies in sustainable, high-purity raw materials — and Synthetic Fluorspar manufacturers are at the center of this transformation. Companies like Tekor Minerals are pioneering innovative production methods, ensuring consistent supply, and meeting the evolving needs of global industries.

By partnering with Tekor Minerals, businesses secure not just premium synthetic fluorspar but also a competitive edge in quality, cost-efficiency, and sustainability.

Explore premium synthetic fluorspar solutions at Tekor Minerals and elevate your production processes with world-class quality.