Expanded Polyethylene (EPE) foam has become an indispensable material for packaging across a multitude of industries. Its lightweight nature, exceptional cushioning properties, and versatility in Custom EPE Foam Packaging make it a go-to solution for protecting a wide range of goods. From the delicate components of EPE Foam Packaging for electronics and the fragility of EPE Foam Packaging for glassware to the secure transit of other EPE Foam Packaging for fragile items and even bulky furniture, EPE foam plays a crucial role in ensuring products reach their destination safely in markets spanning Mumbai, Navi Mumbai, Thane, Panvel, the USA, UK, and Australia. This comprehensive guide explores the key industries that rely heavily on EPE foam packaging, highlighting the specific benefits it offers to each.

The Unrivaled Protection: Why Industries Choose EPE Foam

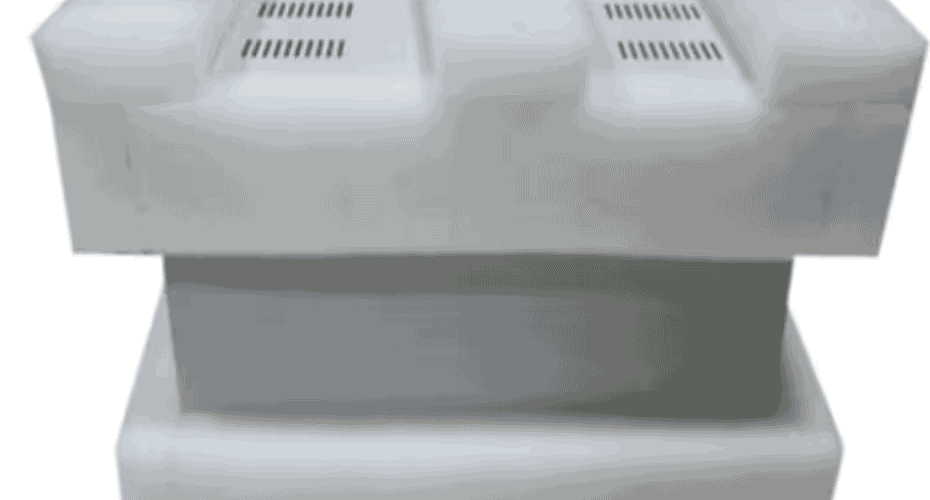

EPE foam’s closed-cell structure provides superior shock absorption and vibration dampening. This is critical for safeguarding sensitive products during the often-rough handling of shipping and transportation. Its water resistance, thermal insulation properties, and non-abrasive nature further contribute to its widespread adoption across diverse sectors. The ability to create Custom EPE Foam Packaging tailored to specific product needs solidifies its position as a premier packaging material.

Key Advantages of EPE Foam Packaging:

- Superior Cushioning: Protects against impacts and vibrations.

- Excellent Shock Absorption: Minimizes damage during transit.

- Lightweight: Reduces shipping costs.

- Water Resistant: Shields against moisture damage.

- Thermal Insulation: Protects temperature-sensitive goods.

- Non-Abrasive: Prevents scratches and surface damage.

- Versatile Customization: Can be molded, cut, and shaped to fit any product.

- Cost-Effective: Offers excellent protection at a reasonable price.

- Recyclable: An environmentally conscious packaging choice.

These benefits make EPE foam an essential component in the supply chains of numerous industries worldwide.

Electronics Industry: Safeguarding Delicate Technology

The electronics industry is a major consumer of EPE Foam Packaging for electronics. Electronic devices are often delicate and susceptible to damage from shocks, vibrations, and electrostatic discharge (ESD). Custom-designed EPE foam inserts provide crucial protection for items ranging from smartphones and laptops to circuit boards and sensitive components.

Examples in the Electronics Industry:

- Smartphones and Tablets: Custom-molded EPE foam cradles secure devices within retail packaging and during shipping from manufacturers in Panvel to consumers in the USA.

- Laptops and Computers: EPE foam padding and corner protectors offer vital protection against impacts during transit to retailers in the UK.

- Circuit Boards and Components: Anti-static EPE foam packaging prevents electrostatic damage to sensitive electronic components shipped between suppliers in Thane and assembly plants in Australia.

- Televisions and Monitors: Large EPE foam blocks and edge protectors safeguard screens from cracks and scratches during distribution to stores in Mumbai.

The precise fit and cushioning provided by Custom EPE Foam Packaging are essential for minimizing damage and ensuring the integrity of electronic goods.

Glassware and Ceramics Industry: Protecting Fragile Items

The fragility of glassware and ceramic products necessitates robust and carefully designed packaging. EPE Foam Packaging for glassware provides excellent cushioning and prevents movement, significantly reducing the risk of breakage during shipping and handling. Custom EPE foam inserts create individual compartments, separating delicate items and absorbing shocks.

Examples in the Glassware and Ceramics Industry:

- Wine Glasses and Stemware: Custom EPE foam dividers and molds secure individual glasses within boxes, preventing them from colliding during transport to restaurants in London.

- Ceramic Vases and Pottery: Shaped EPE foam inserts provide all-around protection for delicate ceramic items shipped from artists in the UK to galleries in the USA.

- Laboratory Glassware: Precision-cut EPE foam packaging ensures the safe transit of fragile beakers, flasks, and test tubes between research facilities in Australia.

- Dinnerware Sets: EPE foam layers and dividers protect plates, bowls, and cups from chipping and breaking during distribution to retailers in Navi Mumbai.

The shock-absorbing properties and customizable nature of EPE foam are crucial for minimizing damage to fragile glassware and ceramic products.

Furniture Industry: Preventing Scratches and Damage During Transit

While not always the primary packaging material, EPE foam plays a significant role in the furniture industry. Its non-abrasive surface and cushioning properties protect furniture pieces from scratches, dents, and other damage during manufacturing, storage, and transportation to showrooms and customers in cities like Sydney and Manchester.

Examples in the Furniture Industry:

- Tabletops and Wooden Panels: EPE foam sheets and corner protectors prevent scratches and dents during transport from factories around Mumbai.

- Upholstered Furniture: EPE foam wrapping protects fabric and leather surfaces from scuffs and tears during delivery to customers in the USA.

- Fragile Furniture Components: Custom-cut EPE foam blocks and inserts secure delicate parts like glass shelves and decorative elements during shipping between manufacturers in Thane and assembly plants in the UK.

The non-abrasive and cushioning qualities of EPE foam help maintain the pristine condition of furniture throughout the supply chain.

Automotive Industry: Protecting Parts and Components

The automotive industry relies on EPE foam for packaging various parts and components, from delicate sensors to larger molded pieces. Its shock absorption and non-abrasive properties ensure that these parts arrive at assembly plants in areas like Detroit and Birmingham without damage.

Examples in the Automotive Industry:

- Electronic Sensors and Control Units: Custom EPE foam trays and inserts protect sensitive electronic components from vibration and impact during transport to car manufacturers.

- Molded Plastic Parts: Shaped EPE foam packaging secures bumpers, dashboards, and interior trim pieces, preventing scratches and deformation during shipping.

- Glass Components: EPE foam profiles and separators protect windshields and other glass parts from breakage during transport to assembly lines.

The durability and customizable nature of EPE foam make it ideal for the demanding requirements of automotive parts packaging.

Medical and Healthcare Industry: Ensuring Sterility and Protection

The medical and healthcare industry requires packaging that not only protects delicate instruments and devices but also maintains sterility. EPE foam, with its non-reactive and cushioning properties, is used for a variety of medical packaging applications.

Examples in the Medical and Healthcare Industry:

- Surgical Instruments: Custom-cut EPE foam trays hold delicate surgical instruments securely, preventing damage and maintaining sterility during transport to hospitals in London and Los Angeles.

- Diagnostic Equipment: Shaped EPE foam packaging protects sensitive medical devices like scanners and monitors during shipping between manufacturers and healthcare facilities in Australia.

- Pharmaceutical Products: EPE foam inserts can provide cushioning and temperature insulation for certain pharmaceutical products during transit.

The non-reactive and protective qualities of EPE foam are crucial for the safe and sterile transport of medical goods.

Other Industries Benefiting from EPE Foam Packaging

Beyond these major sectors, numerous other industries rely on the versatility of EPE foam packaging:

- Sports and Leisure: Protecting items like helmets, padding, and surfboards during shipping.

- Arts and Crafts: Safeguarding delicate sculptures and artwork during transport between galleries in New York City and Melbourne.

- Industrial Equipment: Providing cushioning and protection for various machinery parts.

- Agriculture: Protecting delicate produce during transportation.

The adaptability of Custom EPE Foam Packaging makes it a valuable asset across a wide spectrum of industries.

The Role of Customization: Tailoring EPE Foam to Specific Needs

The ability to customize EPE foam is a key reason for its widespread use. Manufacturers can create Custom EPE Foam Packaging solutions that precisely fit their products, providing optimal protection regardless of shape or size. This includes:

- Custom-cut inserts: Designed to cradle specific products.

- Molded shapes: Created to match complex product contours.

- Laminated materials: Combining EPE foam with other materials for enhanced properties.

- Anti-static options: Protecting sensitive electronics.

Custom EPE Foam Packaging ensures that products are securely protected, minimizing damage and reducing shipping costs. Suppliers in Mumbai, Navi Mumbai, and Thane play a vital role in providing these tailored solutions.

EPE Foam – A Cornerstone of Modern Packaging

From the intricate components of electronics to the delicate surfaces of furniture and glassware, EPE foam packaging has become a cornerstone of modern supply chains. Its exceptional cushioning, versatility, and customization options make it an indispensable material for a vast array of industries across Mumbai, Navi Mumbai, Thane, Panvel, the USA, UK, and Australia. By providing reliable protection against the rigors of shipping and handling, Custom EPE Foam Packaging ensures that products reach their final destination in perfect condition, safeguarding both the goods themselves and the reputations of the businesses that rely on it. The diverse applications of EPE foam underscore its crucial role in facilitating global commerce and protecting the products we use every day.

Best Searchable Keyword Variations

- Industries using EPE foam for packaging solutions

- Benefits of EPE foam in electronics packaging

- Why glassware industry relies on EPE foam protection

- EPE foam applications in furniture shipping

- Automotive parts packaging with custom EPE foam

- Medical device packaging using EPE foam inserts

- Cost-effective EPE foam packaging for fragile goods

- Custom EPE foam solutions for industrial products

- Lightweight protective packaging with EPE foam

- Sustainable EPE foam packaging applications